Presentation at the GS1 Healthcare Conference by Dijklander Hospital

At the 37th Global GS1 Healthcare Conference held in Paris on November 15-17, 2022, Diederik Rood, Senior Adviser, National Implant Register project, Dijklander Hospital Hoorn, presented during the breakout session:

‘Why product master data is essential for patient safety‘.

Dijklander Hospital

Dijklander Hospital and Type 2 Solutions have been working together since 2019 in the field of product master data.

Linking to GS1 GDSN

Dijklander Hospital uses the GDSN Mapping service to retrieve data from GS1 Data Source Healthcare. By linking to GS1 Data Source Healthcare (GDSN), Dijklander Hospital gained direct access to the data of the total range of suppliers with hundreds of thousands of articles.

Data Quality Dashboard

Dijklander Hospital uses the Data Quality Dashboard to monitor, maintain, and optimize the product master data.

By using the GS1 standards in their ERP system AFAS and Electronic Healthcare Record system HiX they have automated and improved the Operating Room logistics. It also enabled them to comply with laws and regulations such as the National Implant Registry (LIR).

Read the presentation of Diederik below and download the slides.

Diederik Rood on stage at the Global GS1 Healthcare Conference.

Why qualitative product master data is essential for patient safety

Presentation by Diederik Rood

“Dijklander hospital is a hospital located in Purmerend and Hoorn. At the hospital I work as a Senior adviser with projects in purchasing, finance, and logistics and I lead the National Implant Register project together with Marije Bakker.

During this presentation I will give you an overview on how we use GS1 GDSN master data within our organization and how we try to improve our master data by using GS1 standards and the data quality dashboard.”

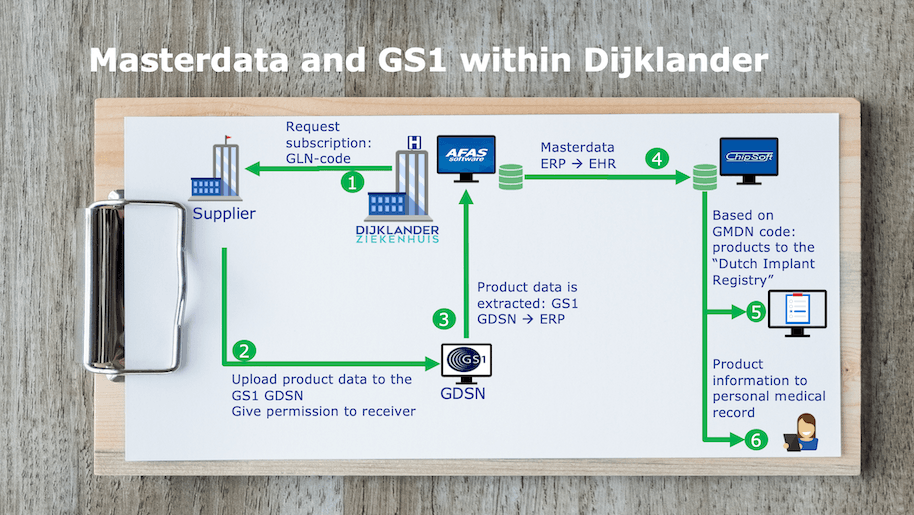

How do we use GS1 master data within our organization?

- We have a subscription based on the GLN number with our suppliers/manufacturers.

- The suppliers upload their product data in the GS1 GDSN, which here looks quite easy, but we have seen how difficult that is for suppliers/manufacturers.

- Based on the GTIN or the external reference code product information is extracted from the GS1 GDSN and supplemented to our ERP System.

- By connecting our product master data between our ERP system AFAS and our Electronic Healthcare Record HiX (ChipSoft), we use the GS1 information in our Electronic Healthcare record as well. This makes it possible to scan implants in the operating theatre as well.

- Based on the product information we comply to registries such as the Dutch implant registry (LIR), which is good for patient safety, and we can,

- Send the product information to the personal medical record of patients, so that patients have access to their product information in their own medical record.

Masterdata and GS1 within Dijklander Hospital.

Use GS1 GDSN to comply with regulations and registries

Diederik continues:

“The master data enables us to scan products in the hospital logistics supply chain, which improves reliability and efficiency. We use the product data of the GS1 GDSN to comply with regulations and registries, for example the GMDN code and the risk class. Others give extra product information which are very useful, such as contains latex, is sterile. But to be able to have all these benefits, you really need high qualitative data, and that the data is trustworthy.”

Need for high qualitative data

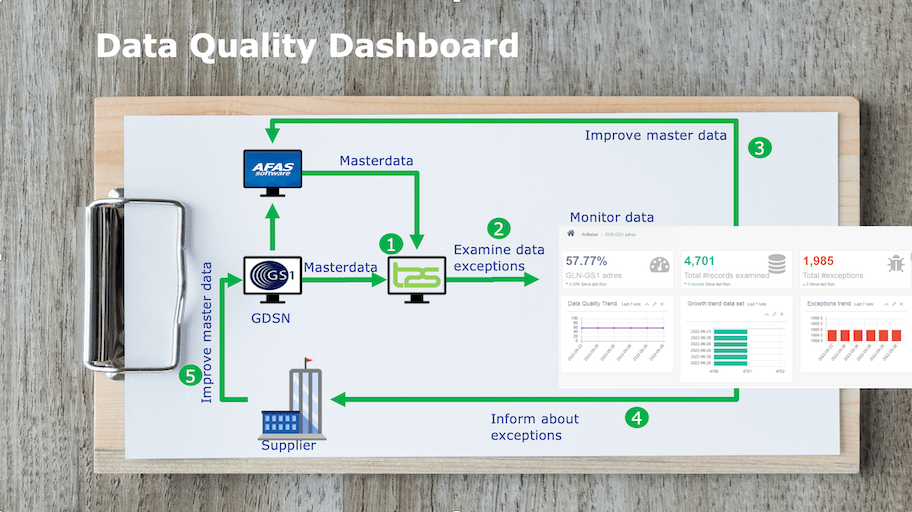

“That’s why we thought: what’s our data quality? How can we monitor our data quality. That’s where we met Type 2 Solutions. They developed together with us the Data Quality Dashboard.

The data quality monitor is an online dashboard that tracks and measures the quality of our data and helps improve our data quality in a structured way.”

How does it work?

- By combining the master data in our ERP system AFAS with the master data of the GS1 GDSN, and uploading this to the Data Quality Dashboard, we can monitor and compare our data quality.

- Based on data rules, our data is examined, and the exceptions are shown in the data quality dashboard.

- Based on that information, we can improve our own master data in our ERP system by inserting missing or incorrect data.

- We can also inform suppliers/manufacturers if we have missing information in the GS1 GDSN, so that they can improve their master data in the GS1 GDSN.

- So that we in the end can import that data in our ERP system and in that way keep on improving our master data quality.

The Data Quality Dashboard at Dijklander Hospital.

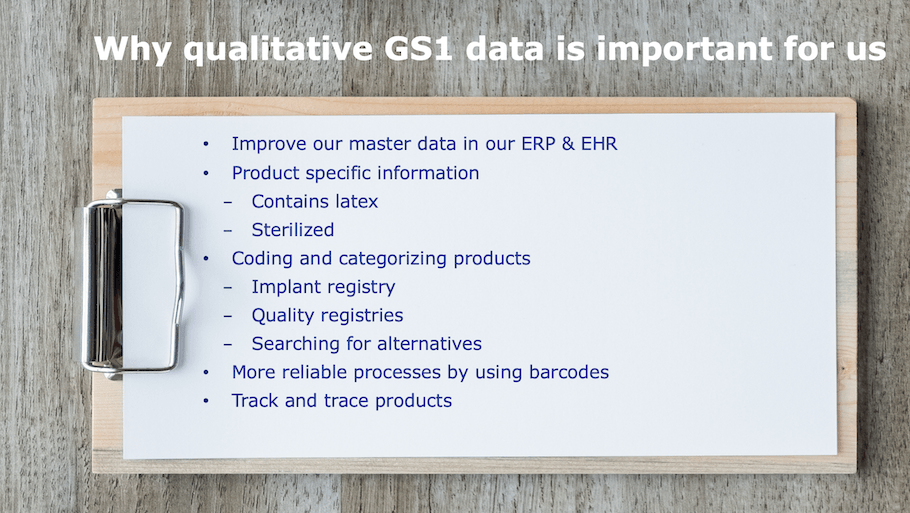

Why qualitative GS1 data is important

“To summarize why GS1 master data is important for our hospital and, in the end, patient safety.

With the information of the GS1 GDSN, we can:

- Improve our master data in our ERP & EHR

- Have more product specific information such as ‘contains latex’ and ‘sterilized’

- Code and categorize products better for the Implant registry (LIR) and other quality registries, as well as search for alternatives

- Have more reliable processes by using barcodes

- Track and trace products efficiently, for example if there is a recall.”

Why qualitative GS1 data is important for Dijklander Hospital.

Call for correct data

Diederik concludes his presentation by emphasizing how important it is that suppliers manage and supply their product master data diligently.

“The software does its job, but without correct and complete data we still cannot provide accurate information to LIR and patients. Especially with legislations like the MDR, which increases the amount of information that needs to be registered, the importance of correct data only increases.

We can only achieve this if we co-operate to build a strong chain.”

Would you like to start with data quality?

Data is a crucial production factor, and high-quality data will boost your daily operations. Optimizing and maintaining data quality requires two things: a good plan and discipline.

T2S gives you the tool to make data work: the Data Quality Monitor. The fast and easy tool that tracks the quality of your data.

Would you like to start monitoring data quality within your organization? Our data specialists help you on your way with our 5-step plan for data quality and the Data Quality Scan.

Healthcare client cases

As a GS1 implementation partner we help healthcare organizations to meet the GS1 standards with our data and label management software solutions and expertise. Click on one of the below images to read more.

Thank you for visiting us at ICT & Logistics 2024

Thank you for visiting us at ICT & Logistics 2024  T2S sponsors the Benchmarking OR Congress

T2S sponsors the Benchmarking OR Congress