12 do’s and don’ts in the field of label management

Although standardization is steadily increasing in the logistics sector, it remains difficult to place the right label in the right place on a pallet or product. Which leads to irritation because the next link in the chain will not be able to properly process it.

How to handle label management, smartly?

Logistiek.nl and VMT.nl interviewed Judith de Witte, sales and marketing manager of Type 2 Solutions, a GS1 implementation partner, on this subject.

“We see that a lot still goes wrong in the field of labeling in the supply chain. If labels are wrong, you will receive an error message upon receipt and the goods cannot be booked in. This permeates the entire chain, and yes, it brings costs and dissatisfied customers.”

Complexity of the GS1 standard

This is partly due to the complexity of the standard. “You need knowledge of GS1 to handle it properly.”

Top 3 points of attention

The interview resulted in twelve do’s and don’ts .

The Top 3 points of attention are:

1. Take a good look at your internal and external business processes. Which labels are needed to make it run smoothly? What information should be on the labels?

2. Look at data quality: which data is in my system and how accurate and complete is the data?

3. Assemble a project team with people from IT, logistics and the business. As a customer and supplier, work together in the chain.

Read further?

Open the Logistics magazine, go to logistiek.nl or vmt.nl and read on!

Would you like to know more?

Comply with GS1 standards with T2S label management and EDI solutions.

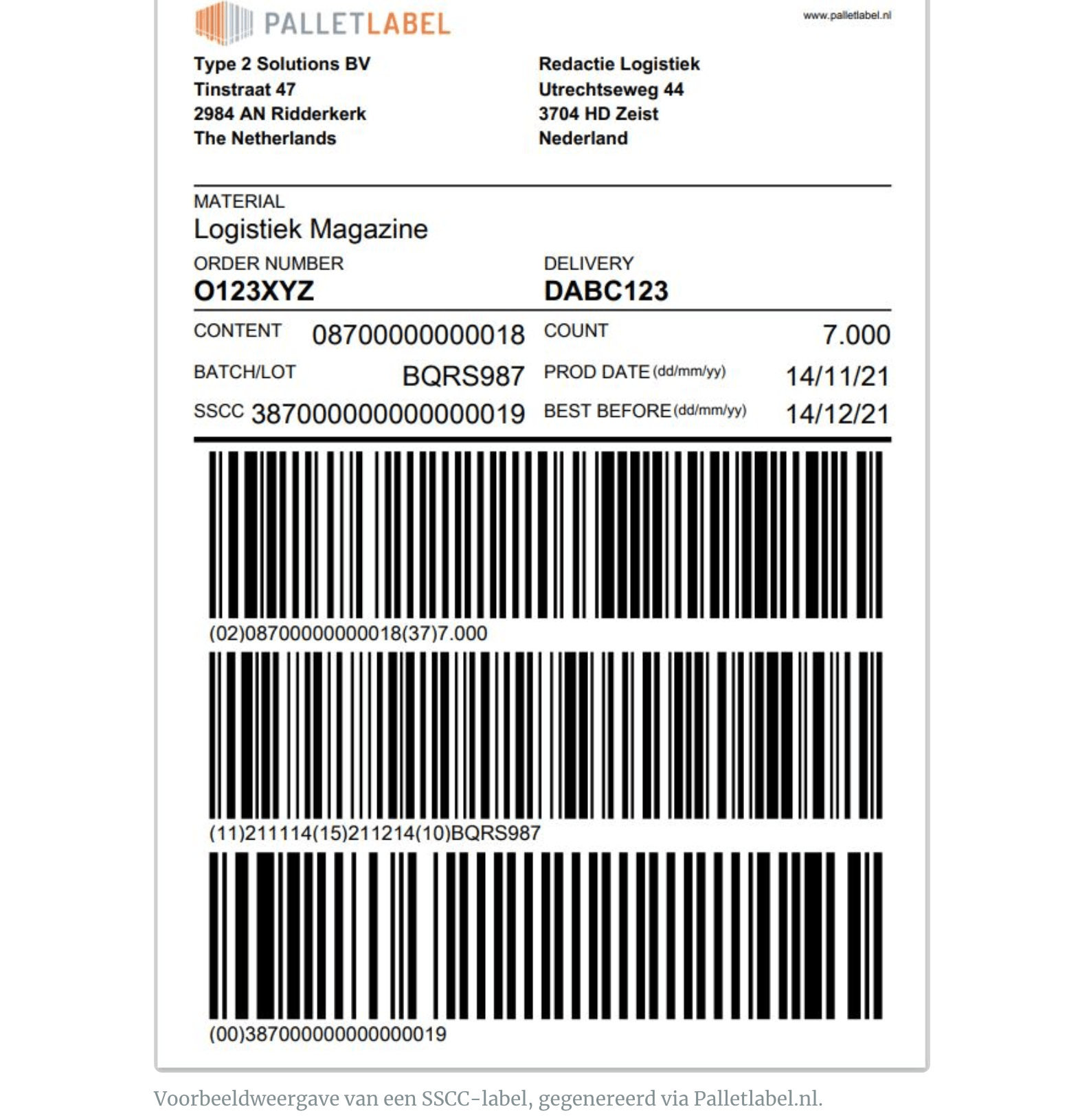

Our versatile suite consists of the Integrated EDI Platform, the EDI Connector, the SSCC-label API, the Software-as-a-Service (SaaS) application Palletlabel and the on-premise solution One2Label Automation.

Discover our suite of barcode labeling and EDI products.

Webinar EDI and SSCC labels

Webinar EDI and SSCC labels  Thank you for visiting us at ICT & Logistics 2024

Thank you for visiting us at ICT & Logistics 2024